As Good As New — That’s the Power of Kaneka Superior Repair Resin SR6400

Kaneka Aerospace is introducing a newly developed two-part epoxy-amine resin to the composite repair market.

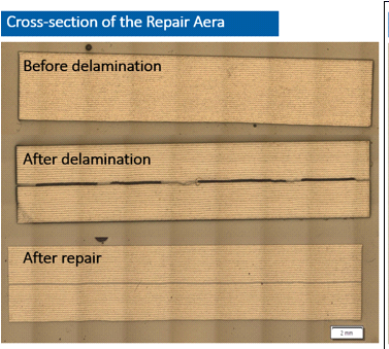

When composite damage occurs, SR6400 doesn’t just repair—it returns the performance to the original state.

This product was identified as the top-performing candidate for composite delamination injection repair in a recent NAVAIR technical paper.

What sets it apart:

- Ultra-low viscosity for deep access into damaged zones

- On-site repair: gels at room temp, cures at lower temperature

- Delivers the highest Tg in its class—more heat resistance, more confidence

- Maintains strength in hot-wet conditions—ensuring long-term reliability

- Lowest post-injection porosity for cleaner, stronger repairs

👉Want to see the difference in your next composite delamination repair?

Request Your FREE Sample Today

📄Need technical details or handling info?

View the TDS and SDS

This product could be used for carbon and glass fiber composites in any industry , such as aerospace, defense, wind energy, marine, industrial, and transportation composites repair environments where reliability and durability are critical.

Along with its mechanical performance, SR6400 offers clear shelf life guidance: Part A remains stable for 12 months at ambient temperature or up to 24 months when refrigerated, while Part B has a consistent 24-month shelf life under both conditions.

Chosen and highly rated by NAVAIR. Built for MRO. Ready to Perform.